Navigating the Future: Supply Chain Optimization Part 1

Welcome back to our series on Supply Chain Trends! In our previous posts, we explored the latest trends in technology, manufacturing, warehousing, logistics, and fulfillment. Now, let’s dive into the critical topic of supply chain optimization, which we’ll explore over two insightful parts.

Supply chain optimization is a strategic approach aimed at enhancing the efficiency and effectiveness of a company’s supply chain operations. This optimization can be grouped into several key disciplines:

- Data & Analytics

- Flexibility & Agility

- eCommerce

- Supply Chain Collaboration

- Sustainability

In this first installment, we’ll delve into the trends driving optimization within Data & Analytics and Flexibility & Agility. Stay tuned for our follow-up post where we will explore eCommerce, Supply Chain Collaboration, and Sustainability.

Data & Analytics: Transforming Supply Chain Management

Data and Analytics play an increasingly crucial role in organizational efforts to optimize supply chains. By using advanced analytical techniques to process and interpret vast amounts of data from various supply chain activities, companies can improve efficiency, reduce costs, enhance decision-making, and facilitate collaboration. Here are three key trends in data and analytics driving supply chain optimization:

-

The Power of Predictive Analytics

Imagine being able to predict future demand accurately, ensuring you always have the right inventory at the right time. This is the power of Predictive Analytics. Using advanced algorithms and AI, predictive analytics allows companies to forecast demand, optimize inventory, reduce operational costs, and enhance logistics. Companies like DHL, UPS, and Amazon are already reaping the benefits.

-

Harnessing Big Data

Big Data is revolutionizing supply chain management by providing actionable insights from vast amounts of data. By analyzing real-time data from various sources, companies can make more informed decisions, predict demand accurately, and streamline their processes.

-

Embracing Digital Supply Chain Twins

A Digital Supply Chain Twin is a virtual simulation of your physical supply chain, allowing you to test scenarios and predict outcomes. This technology helps organizations understand the impact of decisions and disruptions, enabling more resilient and efficient operations. Companies like PepsiCo and General Motors are leading the way with this innovative technology.

Flexibility & Agility: Adapting to a Dynamic Market

Flexibility and Agility are essential for modern supply chains, enabling them to respond swiftly to market changes and customer demands. Here are seven strategies being pursued to enhance flexibility and agility in supply chains:

-

Supply Chain as a Service (SCaaS)

Outsource your supply chain management with Supply Chain as a Service (SCaaS), and focus on your core competencies while enjoying improved efficiency and reduced costs. Giants like Amazon and Hewlett Packard are already leveraging SCaaS to streamline their operations.

-

Elastic Logistics for Dynamic Markets

In today’s fast-paced market, flexibility is key. Elastic Logistics allows your supply chain to scale up or down swiftly in response to demand changes, enhancing efficiency and customer satisfaction.

-

Synchronization-Integration for Seamless Operations

Bridge the gap between your supply chain operations, multi-functional processes, and people systems with Synchronization-Integration. This strategic approach helps manage inventory with precision and improves overall efficiency.

-

Adapting to Rapid Product Life Cycles

With the rapid evolution of product life cycles, especially in sectors like electronics and apparel, supply chains must be agile and efficient. This adaptability is crucial for staying competitive amid constant innovation and consumer preference changes.

-

Smart Logistics for Enhanced Efficiency

Utilize cutting-edge technologies like AI, IoT, and blockchain to optimize your logistics with Smart Logistics. These innovations can reduce costs, improve efficiency, and enhance customer experiences.

-

Omni-Channel Flexibility

Enhance your customer experience through seamless integration across all shopping channels with Omni-Channel strategies. This approach improves inventory management and operational efficiency while enabling data-driven decision-making.

-

Innovating for the Future

Supply Chain Innovation involves adopting new strategies, technologies, and processes to enhance efficiency, reduce costs, and mitigate risks. Staying ahead with innovative solutions is key to meeting customer demands and improving overall performance.

Optimization Questions for Your Organization

As you consider the important insights we’ve shared, asking the following questions within your organization can help evaluate your supply chain optimization strategies:

- Predictive Analytics:

How accurately are we predicting demand? Are there opportunities to leverage AI and advanced algorithms to improve our forecasting?

- Big Data:

Are we fully utilizing the data available to us? What additional data sources could provide valuable insights for decision-making?

- Digital Supply Chain Twin:

Do we have a virtual model of our supply chain to test scenarios and predict outcomes? How could this technology enhance our resilience?

- SCaaS:

Could outsourcing parts of our supply chain management help us focus on our core competencies and reduce costs?

- Elastic Logistics:

How flexible is our logistics network in responding to market changes? Are there areas where we could be more agile?

- Synchronization-Integration:

Are our supply chain operations, processes, and people systems well-integrated? What steps can we take to improve this?

- Product Life Cycles:

How quickly can our supply chain adapt to changes in product life cycles? Are we keeping up with industry innovations and consumer preferences?

- Smart Logistics:

Are we using the latest technologies to optimize our logistics? What potential cost savings and efficiency improvements could we achieve?

- Omni-Channel Strategies:

How seamless is our customer experience across different shopping channels? Are we making data-driven decisions to enhance this experience?

- Innovation:

Are we continuously adopting new strategies and technologies to stay ahead of the competition? What areas of our supply chain could benefit from innovative solutions?

Conclusion

In this first part of our supply chain optimization series, we’ve explored how Data & Analytics and Flexibility & Agility are transforming supply chains. These advancements are crucial for enhancing operational efficiency and maintaining competitiveness in today’s dynamic market landscape.

Stay tuned for part two, where we’ll dive into eCommerce, Supply Chain Collaboration, and Sustainability. Together, these insights will provide a comprehensive overview of how you can leverage innovation to optimize your supply chain strategies and drive success.

Don’t wait—start optimizing your supply chain today! Contact us to learn more and get started on your journey to supply chain excellence.

PAST ARTICLES IN OUR SUPPLY CHAIN SERIES

– Navigating the Future: 9 Ways Tech and AI are Impacting Supply Chains

– Navigating the Future: How Automation is Shaping Supply Chains

Navigating the Future: How Automation is Shaping Supply Chains

Welcome back to our series on trends in supply chains! As we established in our first post, technology is having a dominant and direct impact on supply chains and organizations must strategically adapt in order to stay competitive.

In this post we will dive into four critical pillars (manufacturing, warehousing, logistics, and fulfillment) and critical considerations facing organizations as they assess the future of their supply chains.

Here are the key components shaping each of the four pillars of supply chains:

Examples of critical elements within each pillar are as follows:

1. Manufacturing:

- Digital Transformation: IoT, machine learning, and AI drive efficiency and innovation.

- Reshoring: Bringing manufacturing back for quality control and shorter supply chains.

- Co-Location: Strategically placing facilities for optimized transportation and asset tracking.

- Footprint Optimization: Analyzing and improving production operations for cost and flexibility.

- Make to Order (MTO): Tailoring production to actual demand to minimize waste.

2. Warehousing:

- Expansion and Automation: Meeting increasing demands with automation.

- Central Warehouses: Addressing last-mile delivery challenges for quicker transit times.

- Warehouse Management Systems (WMS): Enhancing efficiency in inventory management.

3. Logistics:

- Transportation Systems: Use of advanced planning systems for the optimization of shipments, fleets, and transportation routes.

- Driver Retention: Strategies to counteract declining interest in driving careers.

- Crowdsourced Delivery: Using local couriers for cost-effective local deliveries.

4. Fulfillment:

- Automation Integration: Streamlining processes from order to receipt.

- Direct-to-Consumer (DTC): Bypassing intermediaries for stronger customer relationships.

- Fulfillment Software: Supporting inventory, order processing, and shipping logistics.

A common theme spanning all four pillars and facing organizations today is automation. Whether in manufacturing, warehousing or transportation, companies have been investing significantly in automation to realize efficiency improvements, lower costs, increased capacity, predictable maintenance and improved operational performance required to meet an evolving and dynamic business environment.

Examples of automation being employed across these pillars include the following:

Optimizing your supply chain in these four areas and factoring in automation involves a strategic, step-by-step approach to identify inefficiencies, evaluate potential benefits, and implement supporting technology solutions effectively.

The following is a recommended approach for organizations planning to optimize their supply chain and tap into automation opportunities:

Phase 1: Assessment and Analysis

– Identify Pain Points: Begin by identifying inefficiencies, bottlenecks, and challenges within the current supply chain operations. Examples could include high operational costs, low inventory turnover, frequent stockouts or overstock situations, and delays in delivery times.

– Evaluate Current Processes: Map out the current supply chain processes to understand the flow of goods, information, and finances. This helps in pinpointing areas that could benefit from optimization.

– Data Collection and Analysis: Collect and analyze data related to supply chain performance, including lead times, inventory levels, supplier performance, and customer satisfaction metrics. This data will provide a baseline for measuring improvement.

– Technology Audit: Assess the current state of technology within the supply chain. Identify existing technologies and their utilization, integration capabilities, and any gaps that automations could fill.

– Market and Technology Research: Research the latest trends in supply chain automation, including software solutions (like ERP, SCM, CRM systems), hardware (like robotics, IoT devices), and emerging technologies (like AI, blockchain). Understand how these could be applied to address identified pain points.

Phase 2: Strategic Planning

– Define Objectives and Priorities: Based on the assessment, clearly define what the organization aims to achieve with optimization, such as reducing costs, increasing speed, improving accuracy, or enhancing customer satisfaction.

– Feasibility Study and ROI Analysis: Conduct a feasibility study for the proposed optimization solutions, including a cost-benefit analysis and an ROI forecast. Consider the financial, operational, and technical viability of implementing these solutions.

– Vendor Selection and Technology Sourcing: Identify potential vendors and technology partners. Evaluate their offerings, support services, and integration capabilities with existing systems. Select vendors that align with the organization’s objectives and budget.

Phase 3: Implementation

– Testing: Before a full rollout, conduct tests of the solutions in select areas of the supply chain. This allows for evaluating the impact on operations, identifying any issues in a controlled environment and will help to evaluate how ready the organization is to adopt the new technologies and processes.

– Training and Change Management: Develop a training program for employees to familiarize them with the new technologies and processes. Implement change management practices to address resistance and ensure a smooth transition.

– Deployment: Proceed with the full deployment of the solution, ensuring it is properly configured and aligned with existing systems and workflows.

– Monitoring and Continuous Improvement: After implementation, continuously monitor the performance of the solution. Collect data to measure improvements and identify areas for further optimization. Be prepared to iterate and make adjustments as necessary.

Phase 4: Review and Scale

– Performance Review: Compare post-implementation performance against the objectives and baseline metrics established in the assessment phase. Evaluate the success of the optimization project in terms of efficiency gains, cost savings, and ROI.

– Scaling and Further Automation: Based on the initial implementation’s success, consider scaling the optimization solution to other areas of the supply chain or implementing additional technologies to further optimize operations.

– Feedback Loop: Establish a feedback loop with all stakeholders, including employees, suppliers, and customers, to gather insights on the impact of the new solution and identify opportunities for continuous improvement.

Throughout this process, it’s crucial to maintain flexibility, as supply chain dynamics can change rapidly due to market conditions, technological advancements, or shifts in consumer demand. By following these steps, organizations can ensure a strategic approach to optimizing their supply chain, leading to enhanced efficiency, reduced costs, and improved competitiveness.

The Gunter Group’s consultants offer industry expertise to guide organizations in assessing and optimizing their supply chains and help businesses maximize the impact of their supply chain operations. Stay tuned for our next post, which will explore tools and practices driving supply chain optimization, including supply collaboration, e-commerce, data analytics, and supply chain flexibility.

PAST ARTICLES IN OUR SUPPLY CHAIN SERIES

– Navigating the Future: 9 Ways Tech and AI are Impacting Supply Chains

Navigating the Future: 9 Ways Tech and AI are Impacting Supply Chains

Supply chains are the backbone of the global economy, orchestrating the seamless flow from manufacturers to consumers. They are intricate networks covering vendor selection, raw materials, manufacturing, warehousing, and end-user delivery. Beyond meeting consumer demands, they drive economic growth, create jobs, drive profitability and brand share, and fuel innovation.

In crises like the Covid-19 Pandemic, resilient supply chains shine. Today’s dynamic business landscape demands agile responses to tech shifts, changing preferences, and disruptions. Global supply chains, complex and swift, navigate regulatory changes. Rapid evolution enhances efficiency and cost-effectiveness, enabling organizations to meet demands and conquer challenges. Innovation and data-driven insights are paramount for staying competitive.

In this series of blog articles we will explore the leading trends shaping future Supply Chains. This first article will discuss The Impact of Technology on Supply Chains, with subsequent posts covering the following topics:

– Supply Chain Operations: trends impacting functions such as manufacturing, warehousing and logistics as well as trends in automation.

– Supply Chain Optimization: optimizations such as supply collaboration, e-commerce, data & analytics and supply chain flexibility & agility. The post will also discuss sustainable supply chains.

– People in Supply Chain: the “people” impact resulting from wide-scale changes and how an organization can prepare people for this change.

– Supply Chain Business Environment, Supply Chain Resilience and Change Management: what organizations can expect going forward and how this will impact their supply chains.

Trends in Supply Chain: The Impact of Technology and AI on Supply Chain

In the landscape of global commerce, the importance technology will play in the future of supply chains is paramount. Artificial Intelligence (AI), Cybersecurity, and advanced tools are emerging as pivotal technological components all working together to develop Digital Supply Chains:

- AI brings unprecedented efficiency to supply chain management by optimizing processes, predicting demand patterns, and enhancing decision-making through data-driven insights. Its ability to analyze vast datasets enables organizations to streamline operations, minimize costs, and respond swiftly to market fluctuations.

- Advanced tools, such as Digital Supply Chain Twins, Supply Chain Control Towers, Blockchain and the Internet of Things (IoT) devices foster transparency, traceability, and real-time monitoring, promoting a resilient and agile supply chain.

- Robust cybersecurity measures are indispensable in safeguarding sensitive information, assuring the integrity of transactions and mitigating the risks associated with increasingly complex digital ecosystems.

As technology continues to evolve, its integration into the supply chain not only enhances operational efficiency but also fortifies the sector against emerging challenges, ensuring a future-ready and adaptive foundation for global commerce.

AI is providing exciting advancements in supply chains, as exhibited from the following examples:

- Supply Chain Mapping: AI-driven supply chain mapping involves utilizing artificial intelligence algorithms to analyze and visualize the end-to-end flow of goods, information, and processes within a supply chain, offering comprehensive insights and optimization opportunities. Wal-Mart, Tyson Foods, Maersk and Siemens are real world examples of companies using Supply Chain Mapping to find and engage with alternate suppliers as well as pre-qualify alternate suppliers.

- Machine Learning and Predictive Analytics: Machine learning in the supply chain applies algorithms to learn from data, predict trends, and optimize decision-making. This boosts forecasting accuracy, enhances inventory management, and improves overall operational efficiency. Continuous adaptation to new information ensures a responsive and agile supply chain. Companies like DHL, Maersk, UPS, and Vibronyx Inc. leverage AI-driven predictive analytics to analyze historical data, identify patterns, and forecast future trends, enabling proactive decision-making, risk mitigation, and operational optimization.

- Operational Performance: Specific examples of how AI can optimize operational performance include AI-powered forecasting that can equip operations with improved intelligence to reduce demand-supply mismatches, AI-based algorithms that automate goods retrieval from warehouses for smooth order fulfillment and chatbots to improve customer service. Additional examples include solutions supporting fleet management platforms that optimize routes for a faster and more economical movement of goods and AI-powered autonomous vehicles that can reduce driver costs.

Along with the importance of AI to the future of supply chains, there are various advanced tools, some of which will work hand-in-hand with AI capabilities that will play an important role in supply chains:

- Digital Supply Chain Twin: A Digital Supply Chain Twin is a virtual simulation of a physical supply chain that uses real-time data and artificial intelligence to analyze and predict its behavior. It helps organizations test scenarios, model different options, and understand the impact of decisions and disruptions on network operations. Real world examples of companies utilizing Digital Supply Chains include Google, FedEx, DHL, GE, Rolls-Royce and Pratt & Whitney.

- Supply Chain Control Tower: A Supply Chain Control Tower is a centralized platform that provides end-to-end visibility and real-time monitoring of supply chain activities spanning areas such as transportation, warehousing, inventory management and manufacturing. This enables proactive decision-making, issue resolution, and optimization of logistics processes. Real world examples of companies utilizing Supply Chain Control Towers include Coca-Cola, IBM, Nestle, Procter & Gamble and Unilever.

- Blockchain: Blockchain in the context of the supply chain acts as an immutable and transparent digital ledger, enabling secure and traceable recording of transactions, shipments, and processes across a decentralized network, thereby enhancing trust, reducing fraud, and optimizing transparency throughout the supply chain ecosystem. This technology ensures that each participant in the supply chain has access to a consistent and incorruptible record of transactions, fostering efficiency and accountability. Real world examples of companies utilizing Blockchain include Walmart to track products back to their origin, British Airways and Maersk to manage cargo, and Nestle for their Supply Chain management.

- Internet of Things: The Internet of Things (IoT) in the supply chain embeds sensors and connected devices for real-time tracking and data collection, fostering increased visibility and efficiency. This enables proactive decision-making, optimizing overall supply chain performance. Facilitating seamless communication between devices, IoT enhances management, provides actionable insights, reduces delays, and offers a comprehensive understanding of the entire supply chain ecosystem. Companies like Amazon, Volvo, and Maersk Line use IoT for warehouse management, monitoring car part shipments, and tracking containers globally.

- Smart Logistics: Smart Logistics integrates cutting-edge technologies such as IoT sensors, data analytics, and automation to optimize the entire logistics process, enabling real-time monitoring, predictive analytics, and efficient decision-making for improved supply chain performance. Real world examples of companies utilizing Smart Logistics include Amazon using Kiva robots to move goods efficiently across its fulfillment centers, DHL for better inventory management and forecasting, and Chronicled to automate traceability and instantaneously approve financial transactions in the shipping industry.

- Cybersecurity: Cybersecurity is set to shape the future of the supply chain industry with key trends. The integration of AI and machine learning enhances adaptability to evolving threats. Blockchain technology fosters transparency and traceability. The rise of quantum computing prompts the development of quantum-resistant encryption. Convergence with IoT devices demands robust security protocols. Emphasizing collaboration and adopting a proactive, risk-based approach are crucial for staying ahead of cyber threats as supply chains digitize.

To reiterate the message at the beginning of this post, supply chains must be agile and adaptable to thrive. Enhancements in technology, such as in the tools listed above will play a significant role in allowing your supply chain to meet future challenges. In addition, as organizations begin utilizing these tools, they will also need to ask themselves the following questions to assess their readiness for implementation:

- What is the intention, or future state design of the supply chain, and will the implementation of these tools get the organization to where they need to go?

- Is the organization ready to implement, and if not what is needed to be ready?

- What is the pre-work needed by the organization to use various AI tools across their supply chain. Pre-work will span areas such as data preparation, machine learning pre-work, capital investment planning and training.

Today’s supply chains are far from the simplicity of a few years ago, as captured in this post showcasing key technological trends. At The Gunter Group, our team of consultants has extensive experience spanning numerous industries and organizations. We’re poised to offer valuable guidance, address your questions, and help develop supply chains that tackle the diverse challenges of the future.

Stay tuned for our next post, delving into the intricacies of Supply Chain Operations.

The 5 Keys to Successful Change Management in RevOps

Welcome to the final chapter of our RevOps series, where we’ve delved into the pivotal role of RevOps within digital transformation, how to successfully activate RevOps and practical ways to capitalize on RevOps functions through specific metrics. As we conclude this journey, it’s evident that RevOps isn’t just a buzzword – it’s a strategic force that brings together sales, marketing, and customer success teams to propel organizational growth. Yet, implementing RevOps goes beyond a mere structural shift; it necessitates effective change management and enablement structure to ensure a seamless transition and long-term success.

While we’ve touched on the subject of change management many times, including an overview of different approaches, this blog will zoom in on the nuances of change management and explore the intricacies of navigating sustainable change within the dynamic framework of Revenue Operations.

The Change Management Imperative

Change is rarely easy, particularly in established organizations with ingrained structures and processes. Successful RevOps requires a cultural shift, and effective change management is crucial. Key strategies to navigate this transformative journey include:

- Cross-Organizational Leadership Buy-In

Cross-organizational leadership buy-in is essential for successful RevOps implementation. While the initial focus may be on marketing, sales and customer success, ultimately each organizational unit will need to understand its role in the revenue generation cycle. RevOps signifies a shift toward collaboration, breaking down silos for a unified revenue approach. Without widespread leadership support, there’s a risk of resistance and slow adoption. Comprehensive buy-in accelerates acceptance, fostering an empowered culture that embraces change. This ensures the benefits of RevOps are fully realized across the organization, creating a more agile and customer-focused company. Start with hosting cross-functional workshops or strategy sessions where leaders from sales, marketing, customer success, and other key departments collaborate to understand the common organizational goals and how RevOps can support the efforts.

- Communication is Key

Clear and consistent communication is the cornerstone of successful change management. Leaders must articulate the vision behind RevOps, emphasizing the benefits it brings to both the organization and individual teams. Regular updates and transparent communication about the upcoming changes help alleviate uncertainty and build a sense of shared purpose. Establish a dedicated communication plan, including regular town hall meetings, newsletters, and interactive Q&A sessions. Clearly articulate the benefits of RevOps to both the organization and individual teams. Use diverse channels such as email, intranet, and video messages to ensure a comprehensive and accessible communication strategy.

- Engage Stakeholders Early and Often

Involving key stakeholders from different departments early in the process provides invaluable input for a smoother implementation. Additionally, involving employees in the decision-making process fosters a sense of ownership, making them more receptive to change. Form cross-functional project teams that involve key stakeholders from various departments in the RevOps implementation process. Set up regular feedback sessions and focus groups to gather insights and address concerns around the implementation and post-implementation. Provide a safe digital space in the form of collaboration platforms to encourage open dialogue and feedback.

- Training and Skill Development

RevOps introduces a more integrated approach, requiring teams to acquire new skills and adapt to different tools and processes. Investing in comprehensive training programs ensures that employees are equipped to thrive in the evolving landscape. This not only minimizes resistance but also empowers individuals to contribute effectively to the revamped operations.

- Celebrate Small Wins

RevOps implementation is a journey marked by milestones. Celebrating small wins along the way reinforces the positive aspects of the change. Recognizing and rewarding teams for their efforts helps build momentum and encourages a culture of continuous improvement. Make sure to celebrate your team by communicating their wins throughout the organization via established channels and you may also consider setting up a RevOps milestone based recognition program.

Sustaining the Change and Evolving with Enablement

While change management sets the stage for a successful RevOps implementation, the enablement functions provide the tools and support necessary for teams to excel within the new paradigm. Enablement can be defined as an iterative process of providing tools, training and resources so that the teams can be successful. It is not a one-time training session, it’s a continuous nurturing process. Here’s how organizations can leverage enablement functions to facilitate a seamless transition:

- Technology Enablement

RevOps relies heavily on technology to streamline processes and enhance collaboration. Ensure that teams are proficient in using the integrated tools and platforms introduced. Collaborate with IT to provide necessary support, training, and troubleshooting resources.

- Data and Analytics Enablement

Data is the lifeblood of RevOps. Enable teams to harness the power of data by providing access to relevant analytics and insights. Invest in training programs that enhance data literacy, empowering teams to make informed decisions and drive revenue growth.

- Cross-Functional Collaboration Platforms

Enablement functions should facilitate the creation and adoption of platforms that encourage cross-functional collaboration. Whether through project management tools, communication platforms, or shared repositories, these tools play a crucial role in breaking down silos and fostering a culture of collaboration.

- Continuous Learning and Development

Enablement is an ongoing process. Implement programs that promote continuous learning and development, keeping teams updated on industry trends, best practices, and the evolving landscape of RevOps. This not only enhances individual skills but also contributes to the overall success of the organization.

Conclusion

Implementing RevOps is more than a structural shift; it’s a cultural transformation that requires a delicate balance of change management and enablement functions. By fostering clear communication, engaging stakeholders, celebrating wins, and investing in enablement, organizations can navigate the challenges and position themselves for sustained growth. We hope that through the TGG RevOps Blog series, you have discovered that embracing the RevOps paradigm is about more than revenue; it’s about building a resilient and adaptive organization ready to thrive in the face of constant change.

Previous RevOps Articles:

- Maximizing Revenue and Efficiency: An Inside Look at RevOps

- Impacting the Bottom Line: The Four Pillars of RevOps

- Is Your RevOps Strategy Working? Navigating Revenue Operations for Growth

TGG Named a Top Provider of Digital Transformation and Agile Services

We are excited to share that The Gunter Group was recently named one of the “10 Most Promising Agile Service Providers” in 2023 by CIOReview magazine. CIOReview conducted a nomination process during which TGG was identified for its Agile work, specifically within the area of Digital Transformation. The recognition was part of CIOReview’s special Agile edition in early December.

TGG’s results-driven support for organizations undertaking large-scale digital transformation has proven to be a valuable resource for numerous clients as the imperative for digital transformation grows across industries.

Angela Tekulve, Principal Consultant, commented:

“Our team acts as a force to unite the leadership team, setting them up for success as change agents for their organization. We deliver necessary training, a well-defined roadmap, and a robust plan to guide clients from their present state to the end state.”

When it comes to digital transformation work, TGG leans on its listen-first approach and digital readiness assessment kit to help organizations avoid digital pitfalls like the lack of a shared vision, misaligned culture and change management, under-resourced digital programs, and ambiguous digital operating models.

The TGG tool kit is effective in identifying and evaluating six domains of digital capabilities typically observed in high-performing digital businesses. These include leadership and strategy alignment, customer-focused values, company culture, technology readiness, the process for resourcing, governance, continuous delivery practice (Agile), and existing digital program structure. It is designed to provide a nuanced understanding of organizations’ digital maturity, empowering organizations with first-hand insights into the gaps and opportunities for improvement in the operation models.

When considering the challenges of digital transformations Matt Bader, TGG Partner, acknowledged:

“Common challenges for business leaders undertaking a digital transformation pertain to the cross-functional nature of orchestrating a complex, enterprise-wide change. Divergence of perspectives among senior decision-makers can also present problems, which result in digital transformation efforts often being clouded with confusion and differing interpretations.”

TGG is humbled by the CIOReview recognition and is proud of its ability to unite leadership teams and tailor the approach to their culture and needs for complex, challenging digital transformation initiatives.

Read the full CIOReview profile on TGG here: https://www.cioreview.com/the-gunter-group-tgg

– – –

Interested in learning more about Digital Transformation Readiness? Click here to discover more and download our Digital Transformation Starter Kit.

Is Your RevOps Strategy Working? Navigating Revenue Operations for Growth

In today’s ever-evolving business landscape, achieving sustainable growth is more than just having a remarkable product or service. It’s a complex interplay of various organizational facets that drive thriving enterprises forward. Yet, the process of aligning these functions and optimizing their performance can often feel like a daunting task.

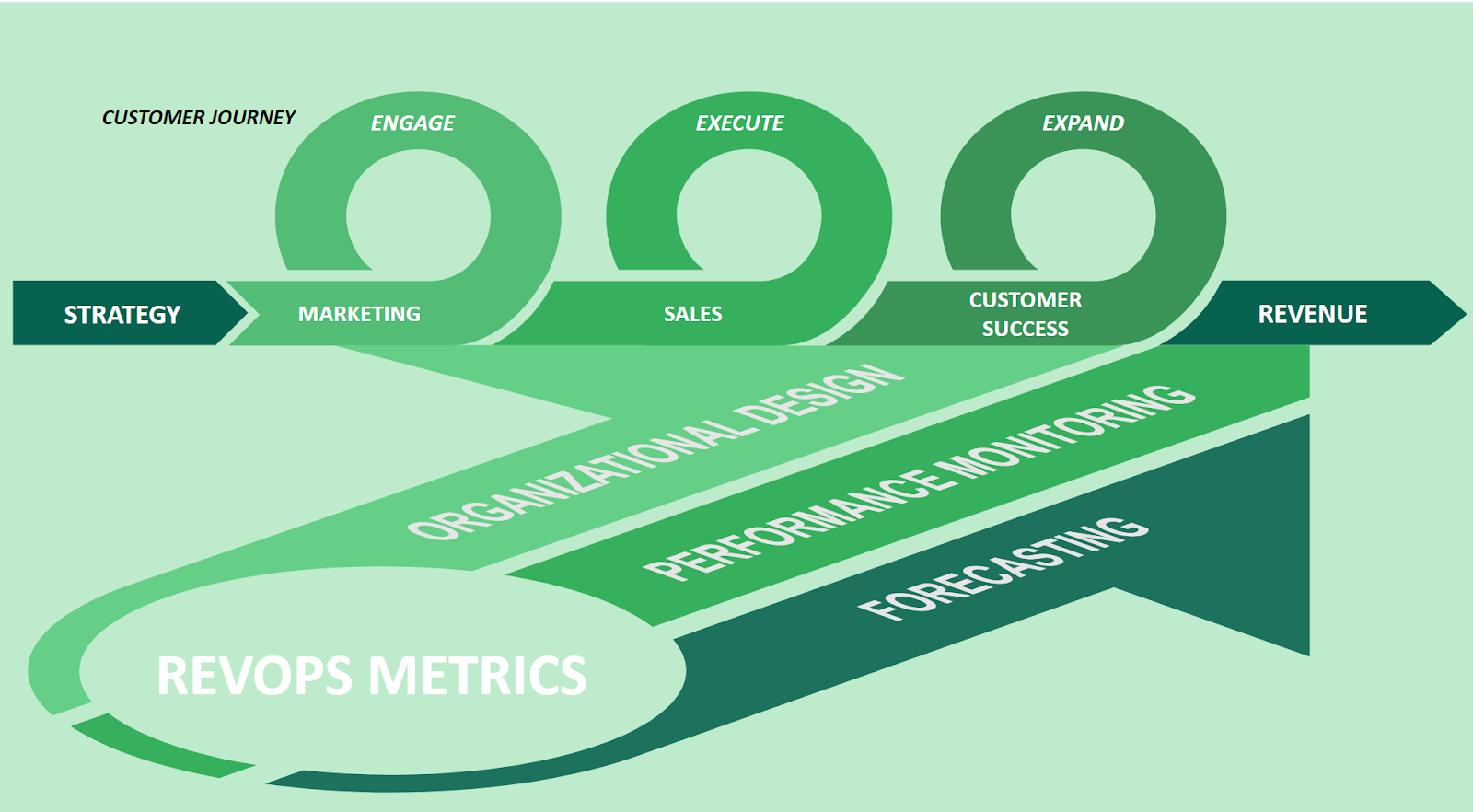

In our previous blog, we delved into the world of Revenue Operations (RevOps), an indispensable strategic framework that acts as the linchpin for your organization. RevOps breaks down silos, fosters collaboration, and harnesses the power of data by aligning your marketing, sales, and customer success teams for maximum impact.

Today, we are diving even deeper into the RevOps data realm, following specific moments during the customer journey that provide valuable operational insights. We will explore critical metrics and how to use data to structure efficient teams as well as to help monitor performance, optimize processes, and forecast revenue effectively.

Before we get into the metrics, it is important to level set on the foundational approach to organizational data:

- Baseline Data Maturity and focus on what you ask of your data

- Level set and understand: All organizations can gain insight from their data, but understanding how mature your data organization is will right-size your ability to create insights.

- Focus and approach: Leaders should ensure they are asking the best questions of their data. When organizations are aligned on what they are asking, then they can create thoughtful metrics.

- Establish Shared Metrics for Alignment

- KPIs for customer journey: Set Key Performance Indicators (KPIs) for the entire customer journey.

- Alignment of objectives: Shared metrics align the objectives of all teams. This shift from department-specific goals encourages a unified focus on overarching objectives like revenue growth and customer satisfaction.

- Foster Transparency and Accountability

- Data sharing and transparency: Teams should have access to data and reporting tools to collaborate and identify areas for improvement.

- Accountability and responsibility: Team members clearly understand performance contributes to shared goals, fostering teamwork and a sense of ownership, particularly when incentives align with these shared goals.

- Monitor Performance to Improve

- Regular performance reviews: Regular performance reviews offer transparency and visibility into each team’s contributions and identifies opportunities for improvement, driving continuous growth and excellence.

Let’s now review specific examples of RevOps metrics that support optimizing your organizational design, facilitate performance monitoring process, and aid with revenue forecasting.

Throughout the customer journey there are key RevOps metrics that provide valuable insights for strategic growth and performance.

- ORGANIZATIONAL DESIGN OPTIMIZATION

- Account Segmentation Analysis: Effective account segmentation is critical to aligning resources with customer needs. By categorizing accounts based on factors such as size, industry, and buying behavior, sales organizations can tailor their approach to meet the unique demands of each segment. Through account segmentation analysis, organizations can align sellers’ experience and capabilities with the needs of the customer, optimizing their journey. The analysis can also help to reveal operational gaps (headcount misalignment or customer service issues) as well as bring to light opportunities (i.e. high value accounts, markets, industries, and white space). In depth segmentation analysis ensures that resources are allocated optimally, maximizing revenue from different customer groups.

- Territory Design: Creating well-defined sales territories ensures that each salesperson is responsible for a manageable and equitable portion of the market. Territory design can be based on geographic regions, industry sectors, customer types, or a combination of any of those criteria. This flexibility allows sales teams to deliver a more personalized and efficient sales experience to prospects and customers in their designated areas.

- Predictive Modeling: Implementing predictive models helps sales teams identify high-potential leads and prioritize their efforts effectively. By analyzing historical data, behavior patterns, and customer demographics, businesses can predict which prospects are most likely to convert, allowing sales reps to focus their attention on those with the highest conversion potential.

- PERFORMANCE MONITORING

- Lead Quality: Measure the quality of leads generated by marketing and passed on to sales. This metric ensures that marketing is delivering leads that are more likely to convert.

- Conversion Rates: Track conversion rates at different stages of the customer journey, from lead to opportunity, opportunity to closed deal, and expansion of existing customers. This helps assess how effectively all teams are moving prospects through the pipeline.

- Customer Retention Rate: Monitor the percentage of customers retained over time. This metric is critical for both sales and customer success teams as it reflects the ability to acquire and retain customers.

- Customer Lifetime Value (CLTV): Understand the long-term dynamic value of a customer. Sales, marketing, and customer success teams play a pivotal role in boosting CLTV by implementing effective cross-selling and upselling strategies. By identifying additional needs and offering complementary products or services, organizations can not only enhance customer satisfaction but also significantly increase revenue from their existing customer base.

- REVENUE FORECASTING

- Monthly Recurring Revenue (MRR): MRR is a foundational metric for businesses especially with subscription-based models, such as SaaS companies. It represents the predictable and recurring revenue generated from subscriptions on a monthly basis. By tracking changes in MRR, RevOps teams can project future revenue with a high degree of accuracy.

- Churn Rate: Churn rate measures the percentage of customers who cancel their subscriptions or stop doing business with your company over a specific period. A high churn rate can erode your revenue, so by forecasting churn, RevOps teams can estimate potential revenue losses and plan strategies to effectively mitigate churn.

- Customer Acquisition Cost (CAC): CAC represents the cost associated with acquiring a new customer. By analyzing historical CAC data and factoring in conversion rates, RevOps can estimate the investment required to acquire new customers in the future. This metric is vital for understanding the scalability of your customer acquisition efforts.

- Sales Pipeline Metrics: Various metrics within the sales pipeline can provide insights into future revenue. These include:

- Pipeline Velocity: The speed at which opportunities move through the sales pipeline. A faster pipeline velocity often leads to shorter sales cycles and higher revenue.

- Opportunity-to-Win Rate: The percentage of sales opportunities that ultimately result in closed deals. By tracking this rate and the value of opportunities, RevOps teams can estimate future revenue potential.

- Sales Forecast Accuracy: By assessing the accuracy of past sales forecasts, RevOps can refine and improve future forecasts. Tracking the deviation between forecasted and actual revenue helps adjust strategies for more precise predictions.

When combined, the above metrics provide a comprehensive view of the factors influencing future revenue. RevOps professionals can use historical data and trends to create models that incorporate these metrics, enabling more accurate revenue forecasts. Accurate forecasting is vital for making informed decisions, allocating resources effectively, and sustaining revenue growth in a dynamic business landscape.

So far our series has taken us through the intricate tapestry of RevOps, a strategic framework that dismantles silos, nurtures collaboration, and harnesses the power of data to align marketing, sales, and customer success teams for unparalleled impact.

By forging a common purpose and creating a shared set of metrics, RevOps aligns these diverse teams toward overarching goals of revenue growth and customer satisfaction. Transparency, data sharing, accountability, and performance reviews become the keystones of a culture that encourages teamwork and shared ownership.

In the end, Revenue Operations transcends mere organizational alignment; it is a commitment to continuous growth, excellence, and a customer-centric approach. In our next installment, we will explore effective ways to enable your teams and manage the change, so that your organization can navigate the ever-changing business landscape with confidence, adaptability, and an unwavering focus on the ultimate destination: sustainable growth and lasting success.

Impacting the Bottom Line: The Four Pillars of RevOps

In the last post, we introduced the concept of Revenue Operations (RevOps) and reviewed seven RevOps objectives in the context of Digital Transformation. In this article, we will explore WHY RevOps should matter to your organization, and what to consider when you decide to integrate RevOps principles in your organization.

Previously, we defined RevOps as a strategic approach that involves aligning and optimizing all revenue-generating functions within an organization. To build on this definition, we will categorize revenue-generating functions based on the revenue life cycle capabilities:

– Lead Generation

– Sales Productivity and Lead Conversion

– Revenue Recognition and Billing

– Customer Success and Retention

Each of these capabilities is essential in the revenue life cycle but when aligned and optimized through RevOps, it can have immense impact on the success of the organization. For example, TGG recently partnered with a client to optimize their sales function to best serve the organization. After an in-depth opportunity analysis, we connected the findings to their customer segmentation analysis, growth targets and seller performance, creating sophisticated models providing leadership with organizational design options and their impact on headcount and account coverage.

– Lead Generation: RevOps ensures that marketing and sales efforts are closely aligned, resulting in higher-quality leads and improved conversion rates. It streamlines processes for lead nurturing and qualification, enabling the efficient allocation of resources to the most promising opportunities.

– Sales Productivity and Lead Conversion: Optimizing sales processes, providing sales teams with the right tools, and offering data-driven insights, RevOps empowers sales professionals to work more efficiently and provides focus for their efforts on closing deals that are more likely to convert. It enables real-time visibility into the sales pipeline, allowing for proactive problem-solving and timely interventions to move deals forward. This, in turn, leads to shorter sales cycles and improved win rates.

– Revenue Recognition: The process of formally accounting for the revenue earned and it involves adhering to accounting standards and practices to accurately record and report revenue. Billing and payment processing are also crucial, ensuring that customers receive timely invoices and make payments.

– Customer Success: RevOps principles ensure that customer data is not lost after the sale but is actively used to drive post-sale engagement and satisfaction. This fosters long-term relationships, encourages upselling and cross-selling opportunities, and ultimately contributes to higher customer lifetime value.

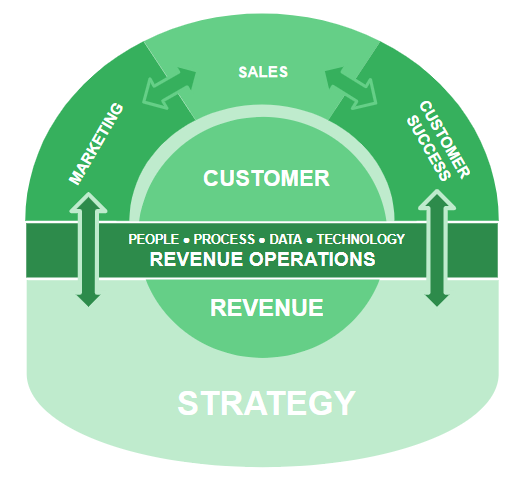

Connecting and streamlining the main capabilities of the revenue life cycle through RevOps, provides a centralized and essential business motor to drive strategic value. By unifying sales, marketing, and customer success functions, RevOps ensures a holistic, data-driven approach to revenue management. This alignment enhances decision-making, maximizes operational efficiency, and provides a deeper understanding of customer behavior. RevOps empowers organizations to adapt quickly to market changes, identify growth opportunities, and scale effectively. In essence, it transforms revenue generation from a siloed, reactive effort into a strategic and proactive engine that propels business growth and success, making it a backbone function for any forward-thinking company.

Now that we understand the WHY behind RevOps, let’s explore the HOW – that is – how to deploy RevOps. As with every transformation, it involves four key pillars: people, process, data, and technology. Let’s delve into each aspect to understand how to successfully roll out this essential function.

PEOPLE

Building a capable RevOps team is the first and crucial step. RevOps professionals need to possess a unique blend of skills, including sales, marketing, finance, and data analytics. Start by clearly defining roles and responsibilities, then invest in training and make sure to keep your RevOps team updated on industry trends and tools. The most critical activity is to encourage collaboration between marketing, sales and customer success teams to ensure alignment and understanding of a shared vision.

PROCESS

Streamlining revenue-related processes is the cornerstone of RevOps. Start by mapping out your customer journey and end-to-end revenue process that support the customer journey, from lead generation to customer retention. Identify gaps, bottlenecks and inefficiencies in the existing processes. Develop a roadmap to address or preferably eliminate them. Develop and implement sales enablement strategies to equip your sales team with the right resources, content, and tools.

DATA

Harness the power of data – it is the core of well functioning RevOps. Start with ensuring that your customer data is centralized, consistent and accessible. Implement robust analytics and reporting tools to gain insights into sales performance, customer behaviors and revenue life cycle. Above all, value customer trust by prioritizing data security and assuring compliance with relevant regulations. To learn more how to assess your organization’s data maturity, click HERE.

TECHNOLOGY

Markets are saturated with numerous tools that claim to be the be-all and end-all of any given application type, so pick your tools wisely and be very selective. Identify technology gaps in the processes and look for tools that can not only fill those gaps but also add efficiency. Work with your technology team to ensure that the selected tool can be seamlessly integrated into your organizational ecosystem. You want to avoid creating data and/or process silos by adding new applications. Regularly assess the performance of your technology stack and make adjustments as needed to assure technology is efficiently supporting your people, processes and data.

As you strategize putting RevOps into action, remember that it’s not a brief project; instead, it’s a meticulously orchestrated transformation that requires deliberate change management practices and adept communication. We will explore this topic more later in this series.

In summary, the Revenue Operations function involves more than just adopting new tools; it’s a holistic approach that requires attention to people, processes, data, and technology. By assembling the right team, streamlining processes, harnessing data, and investing in the right technology, your organization can position itself for sustainable revenue growth and operational excellence. Embrace the RevOps approach, and you’ll be better equipped to adapt to the ever-evolving business landscape and drive success in the long run.

At this point, we shared with you WHERE RevOps fits in the context of Digital Transformation, WHAT RevOps is, WHY it should be important to your organization and HOW to implement it. As we continue with this series, next, we will explore different metrics that will help you organize for success, optimize performance, and maximize revenue.

Maximizing Revenue and Efficiency: An Inside Look at RevOps

In the fast-paced and ever-evolving digital landscape, businesses must embrace change and adapt to stay ahead of the competition. Digital transformation has emerged as a crucial catalyst for success, enabling organizations to optimize processes, enhance customer experiences, and drive innovation. As a resource to support industry professionals, TGG has created a detailed guide to a successful digital transformation that you can download HERE. In the upcoming series of articles, we will be focusing on one aspect of the digital transformation process that often gets overlooked yet is essential for business existence and success: Revenue Operations (RevOps).

The Role of Revenue Operations in Digital Transformation:

RevOps can be defined at a high level as a strategic approach that involves aligning and optimizing all revenue-generating functions within an organization.

Traditionally, businesses have operated in silos, with each department focused on its own objectives, leading to fragmented workflows and inefficient processes. Revenue Operations seeks to bridge these gaps and align various functions like marketing, sales, and customer success to work in harmony towards a common goal – generating revenue.

Digital transformation accelerates the need for RevOps, as businesses must adapt to the changing customer behavior and preferences in the digital realm. Embracing data-driven strategies, automation, and analytics allows companies to gain insights into their operations, improve overall efficiency and ultimately support revenue growth.

The Goals of Revenue Operations

In our experiences supporting client partners through impactful Digital Transformations and RevOps initiatives, successful RevOps have seven main goals. Each of these goals plays a vital role in supporting strategic outcomes.

1. Enhancing Customer Experience: In the digital era, customer experience is king. RevOps aims to unify customer touchpoints and interactions across different departments, ensuring a seamless and personalized experience at every stage of the buyer’s journey. By understanding customer preferences and pain points through data analysis, companies can offer relevant solutions, leading to higher customer satisfaction and loyalty.

2. Maximizing Revenue Growth: At its core, RevOps aims to drive revenue growth. By optimizing processes, reducing inefficiencies, and capitalizing on cross-selling and upselling opportunities, businesses can maximize their revenue potential. The focus shifts from isolated departmental goals to a unified approach, where everyone works together towards generating revenue.

3. Streamlining Sales Processes: Digital transformation brings forth new tools and technologies that can optimize sales processes. From lead generation and nurturing to closing deals, RevOps streamlines the sales journey, eliminating redundancies and improving overall efficiency. Automated workflows, AI-powered sales analytics, and customer relationship management (CRM) software enable sales teams to work smarter and close deals faster.

4. Data-Driven Decision Making: Revenue Operations relies heavily on data analytics to drive insights and decision-making. By centralizing data from different departments, businesses gain a comprehensive understanding of their performance and can identify areas for improvement. Data-driven decision making enables companies to be agile, adaptable, and responsive to market changes.

5. Achieving Sales and Marketing Alignment: Misalignment between sales and marketing can lead to lost opportunities and wasted resources. RevOps aligns the objectives, strategies, and tactics of these two critical functions. By fostering collaboration and communication, RevOps ensures that marketing efforts lead to quality leads that are effectively converted by the sales team.

6. Increasing Scalability: Scalability is a key aspect of digital transformation. As businesses grow and evolve, they must be able to handle increasing demands without sacrificing quality. Revenue Operations establishes scalable processes that can adapt to changing market conditions and support the organization’s growth trajectory.

7. Cultivating a Customer-Centric Culture: In a digitally transformed landscape, customer-centricity is a non-negotiable aspect of success. RevOps fosters a culture that revolves around the customer, where every decision and action is taken with the customer’s needs in mind. This approach creates a positive brand image and builds long-lasting customer relationships.

Digital transformation is not just about adopting new technologies; it is a holistic shift that requires an organization-wide commitment to change and improvement. Revenue Operations plays a pivotal role in this transformational journey by aligning sales, marketing, and customer success, and enhancing customer experiences. The main goals of RevOps revolve around improving efficiency, driving revenue growth, and creating a customer-centric culture. By integrating Revenue Operations into their digital transformation strategy, businesses can unlock the full potential of their operations and position themselves for sustained success in the digital age.

In the following series of articles we will provide you with strategic and applicable information that you can use in your organization. Stay tuned as we explore the Revenue Operations topic in greater detail and dive into RevOps components, implementation approach, key performance metrics, enablement and more. We are looking forward to embarking with you on this journey.

VETERANS AT TGG:

SERVICE, SUPPORT, AND TRANSITION

At The Gunter Group we take pride in hiring consultants from a variety of backgrounds. This purposeful approach results in a diverse team with talent and experiences that deliver meaningful value to our client partners. A key pillar of our award winning team are veterans who served in our country’s military.

Founder Mike Gunter said “The veterans in our company have been fantastic additions to our team. We actively look for team members with backgrounds that are not always typical for consulting, and their experiences and diverse skill sets have allowed them to thrive in our firm. The critical thinking skills necessary to succeed in the armed services translate well into the world of client service, where emotional intelligence, adaptability, and practical solutions are critical”.

Recently we sat down with three veterans and discussed their transition to consulting, what it was like wrapping up their military duties, and advice they have for others transitioning to the private sector.

To get us started, can you share when you joined The Gunter Group and briefly tell us about your military and professional backgrounds?

Liz: I joined The Gunter Group in January of 2022. I previously served almost nine years in the Navy; first as a Surface Warfare Officer and then as a Human Resources Officer, and spent time at the Naval Postgraduate School working on a Master’s Degree in Operations Research. I now serve as a Reservist, as well. With The Gunter Group I’ve had the opportunity to apply my data science skills in our tech services team supporting client engagements.

Brad: After commissioning out of ROTC, I joined the Army in 2013. I served 10 years as an Infantry Officer and am still serving as an Army Reserve Officer. I joined The Gunter Group in February of 2023 and am a certified Project Management Professional (PMP). My transition to TGG was pretty much a straight line as I received the offer letter while still on active duty.

Keith: I was in the Navy for eight years. I started out serving on a Naval ship and then wrapped up my time serving as a Military Policeman (MP). After leaving the Navy I completed my accounting degree as a potential step towards joining the FBI. After doing some accounting and financial work I decided to stay in the accounting and finance industry and worked in various capacities for a number of years. I accepted a position with TGG in November of 2020.

What knowledge, skills, or experiences from your time in the military were beneficial in your transition to management consulting?

Liz: Throughout my various roles in the Navy, I was constantly switching positions and taking on additional collateral duties, and in all those situations, I had limited time to figure out the scope of the work, how I was going to solve a problem, and who could help. To that end it really captured one of TGG’s Non-Negotiables, “Thriving in Ambiguity.” In management consulting I’ve found this skill to be very valuable and used frequently. It’s a skill I started developing heavily in the Navy and is applicable more than ever in the consulting world.

Brad: First off, it’s crucial to emphasize the development of effective people skills and leadership, both formally and in peer roles. In every military career, working with people is vital, especially in Infantry where the individual is the key asset. Effective guidance, supervision, and teamwork are pivotal. I echo Liz’s sentiment about the value of diverse job roles. This resonated with me when I served as a Chief Logistics Officer, and managed complex logistics including supply reception, analysis, resource transportation, and timeline management. These experiences greatly enhanced my move into management consulting.

Keith: I have been out of the military longer than Liz and Brad so my transition timeline looks a bit different. There are certainly skills the military provides that are beneficial to management consulting, especially experiences working with people. I found that in the military I worked with people different from my own background and culture set. There were numerous benefits to this experience and it has been very valuable in consulting.

What was it like when you started the process to transition out of the military? What were some of the questions or concerns you had as you approached the change?

Liz: For me leaving the military, the first big piece was: where are we going to live? However, we also needed a job to anchor the move. The other challenge was being a dual military household and both my husband and I getting out at the same time. Logistics were demanding: time zones for interviews, calendar coordination, moving cross-country with a child. Parental leave and a positive culture mattered, especially since we were planning for another child. The other biggest concern personally and professionally was finding a place with a great culture. Not one that talks about it but really lives it out—where I can transition well, learn, and connect.

Brad: Leaving the military is highly stressful. The military shapes your purpose and identity for most of your adult life. Suddenly, you face the challenge of rediscovering yourself. The first step is understanding who you are beyond the military, which is no simple task. Then comes the question: what’s next? Contrary to belief, not everyone has their post-military path figured out. After research and reflection, I knew I wanted to be a consultant. However, I didn’t want to relocate, living in the same place was a priority.

Keith: It was a little bit different for me because I was enlisted, not an officer. When I was leaving the military I was looking for financial stability and being able to take care of my family. At the time, I had almost finished my degree and I was fortunate enough to have a professor that had contacts in the accounting world and he helped me land my first post military job.

How did The Gunter Group support you during this process and transition?

Liz: In my situation I received my job offer in October and I was not able to start working in my new role until the end of January. The team at TGG set up recurring check-ins until I departed Virginia and stayed in good contact, making sure if I had questions I could receive answers and updates frequently. After that, the onboarding process was very smooth. With a lot of life changes going on, it was really nice how other people recognized I was going through a stressful time. That was something that really stood out to me.

Brad: There were two key ways, starting with the first person I met from TGG, Jim Calko. During my early exploration of consulting firms, Jim took time for meaningful conversations despite my non-employee status. He provided insights, aided my resume, and supported my transition from the military. It was genuine and meant a lot. The second part came during the interview and recruitment phase. TGG’s responsiveness, organization, and swift turnaround eased my already busy situation, turning potential stress into clarity and calmness.

Keith: TGG is the best company I’ve ever worked for first of all. I’m very happy with the people I work with. They are the smartest, kindest people I’ve come across in my career. The management is genuinely concerned about the employees and these characteristics initially revealed themselves during my recruiting and onboarding process and continue to exist on a routine basis year after year. Anytime someone is making a career change the TGG style would be a welcomed support but especially during a post-military transition.

What advice do you have for other military personnel that are about to conclude their service and enter the next phase of their professional career?

Liz: Write down your priorities for big life areas such as: family, work, and location. Then as you think about and evaluate post-military options, reflect on your lists. It’s okay to be picky. Don’t settle for a solution that doesn’t match with your priorities.

Brad: Figure out who you are and what is important to you. Develop a plan and don’t settle for the first thing that comes your way (it will be tempting). It can be beneficial to leverage the programs afforded to you as a transitioning veteran. Personally I found The COMMIT Foundation and American Corporate Partners the most helpful.

Keith: It may sound simple but I’d say to have a plan. Give thought to, and create a plan for what you want to spend your time on once you leave the military. Additionally, it’s incredibly beneficial to have an applicable skill that transitions to civilian life or to have an education plan to further your knowledge in professionally relevant areas.

—

Interested in learning more about how our great culture comes to life? Click here and see what fuels our team, our relationships, and our work.